1.Introduction

In order to achieve fully automated stamping for the products provided by the customer, Dayeepress provide the 16T notching machine Automatic production line with truss for rotor and stator.According to the product drawings evaluation, the feasibility of achieving fully automated stamping is 100%. The automation method adopts a single punch press connected production method, where materials are loaded by the laminating machine and then transported by the truss manipulator. The single punch press automatically stamps, and the products are stacked on the lifting platform, thus combining into a fully automated stamping line.

It consists of 1 unit 16 ton single slot machine, 1 set of molds, 1 truss manipulator, 1 automatic film sorting machine, 1 set of material receiving elevator, and 1 set of control system.

3.Applications

Used to the Silicon steel sheet with an outer diameter of 750-1250mm in circular form for slot punching.

4. Parameters of the slot puncher machine

No. | Name | Unit | Quality |

1 | Slot-puncher | Unit | 1 |

Nominal force | KN | 160 | |

3 | Slide stroke | mm | 20 |

4 | Number of slider strokes (continuous) | Times/minutes | 10-600 |

5 | Table size | mm | / |

6 | Maximum mold opening height | mm | > =25 |

5. Mold Requirements

1)The feeding mechanism and supporting mechanism of the punching machine are normal, and there are feeding trays and supporting mechanisms

2) Positioning of punching machine (customer responsibility)

3) Unified height of lower mold: 70-75mm

4) The fixed core (position) tray is suitable for feeding and picking up automation equipment

5) The locking screw (nut) of the fixed core (position) disc shall not exceed 15mm from the lower mold.

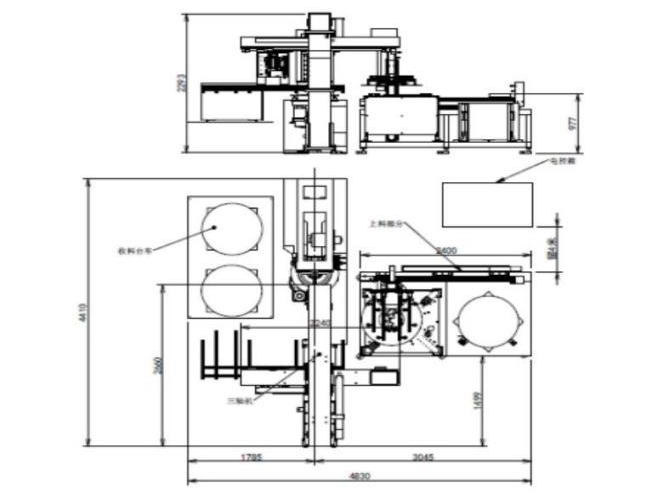

6. Layout of the entire line

7.Workflow

Manually feeding to the wafer positioning → positioning of the material rack on the wafer feeding machine → material retrieval by the truss support arm 1 → punching by the punching machine → material retrieval by the truss support arm 2 from the machine tool punching → material placement by the truss support arm 1 → material placement by the truss support arm 2 on the lifting platform (after completing one round of action by the truss manipulator, the punch press completes one punch, that is, the punch press and truss run asynchronously).

(Handling of processes inside the mold, specific to the final process)

8. Production cycle time

The time for picking and placing materials in the truss (5S)+stamping time (customer set)+automatic replacement time for the fixed rotor stamping mold (3s)=production cycle time.

Production is subject to changes due to factors such as machinery and processes.

Based on the above data, the efficiency of the stamping line depends on the working efficiency of the single slot machine.

The time for individual pick-up and loading is approximately 10 seconds (excluding the first piece).

Contact: Mr. Alexander Wong

Phone: +8618913853250

Tel: +8618913853250

Email: alexander@dayeepress.com

Whatsapp:+8618913853250

Add: No. 66, Taoyuan South Road, Xuzhou Industrial Park (Jiawang District), Jiangsu Province, China 221132

We chat