1.Introduction

Dayee NCLG Three in One Servo Leveling and Feeding Machine is a new type of unwinding and leveling servo feeding integrated machine specifically designed for automatic feeding of thick plates with high yield strength in stamping. The clamping wheel and roller surface are treated with plow low sandblasting and electroplated hard chromium, effectively increasing the friction between the material and the roller, ensuring that the servo feeding process will not slip, and achieving high precision feeding. The outlet is equipped with a new electronic automatic oil coating device, and the oil coating rod is a soft rubber structure, maximizing the uniform application of the oil coating layer on the material surface and effectively protecting the service life of the mold. The equipment adopts a Japanese servo system, pneumatic components, bearings, and electrical components, and the control system adopts a large-sized touch screen with a large capacity user product parameter information memory function. A comprehensive equipment failure alarm system ensures a longer service life for the machine, Higher work efficiency and more reliable safety factor.

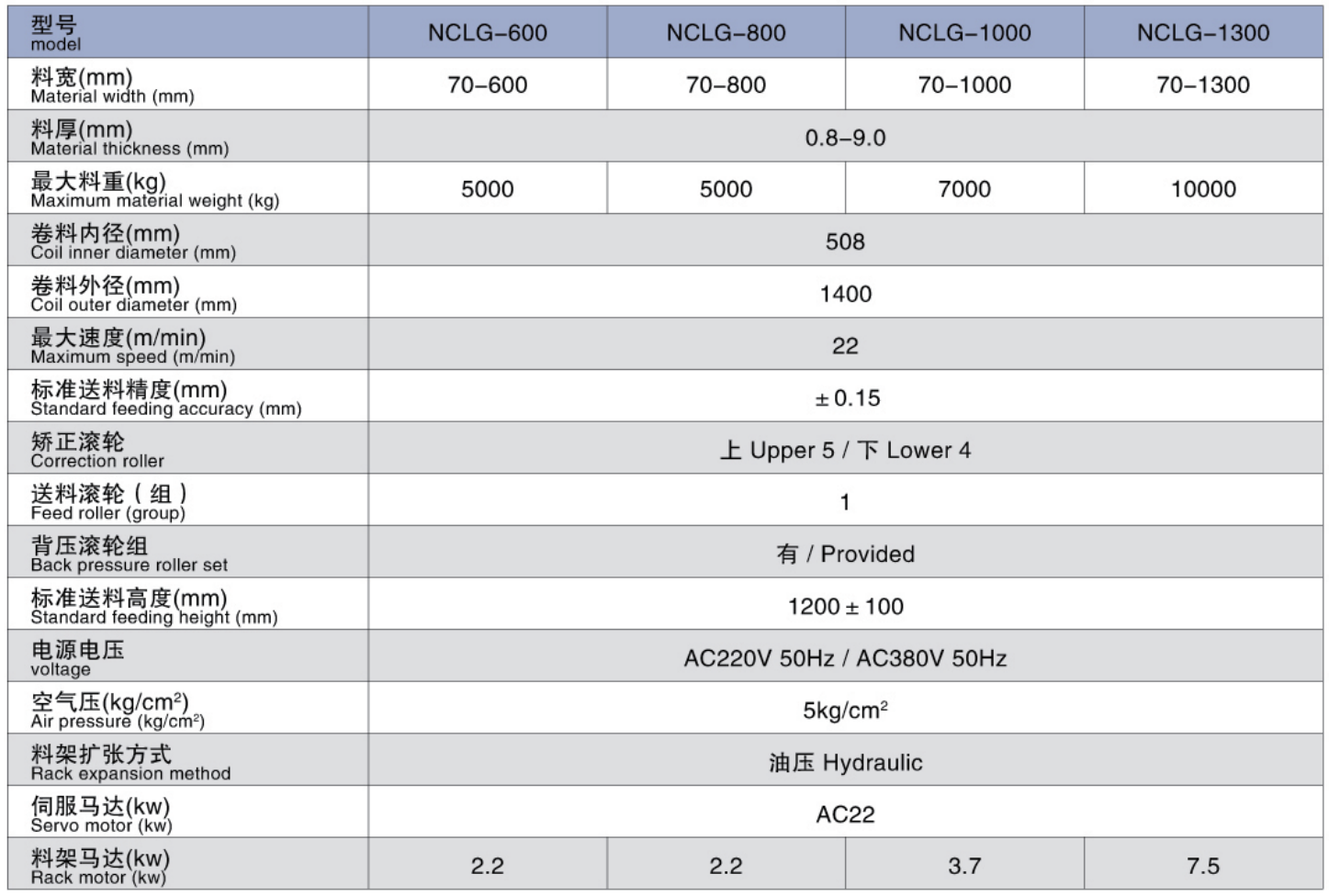

2.Technical specifications

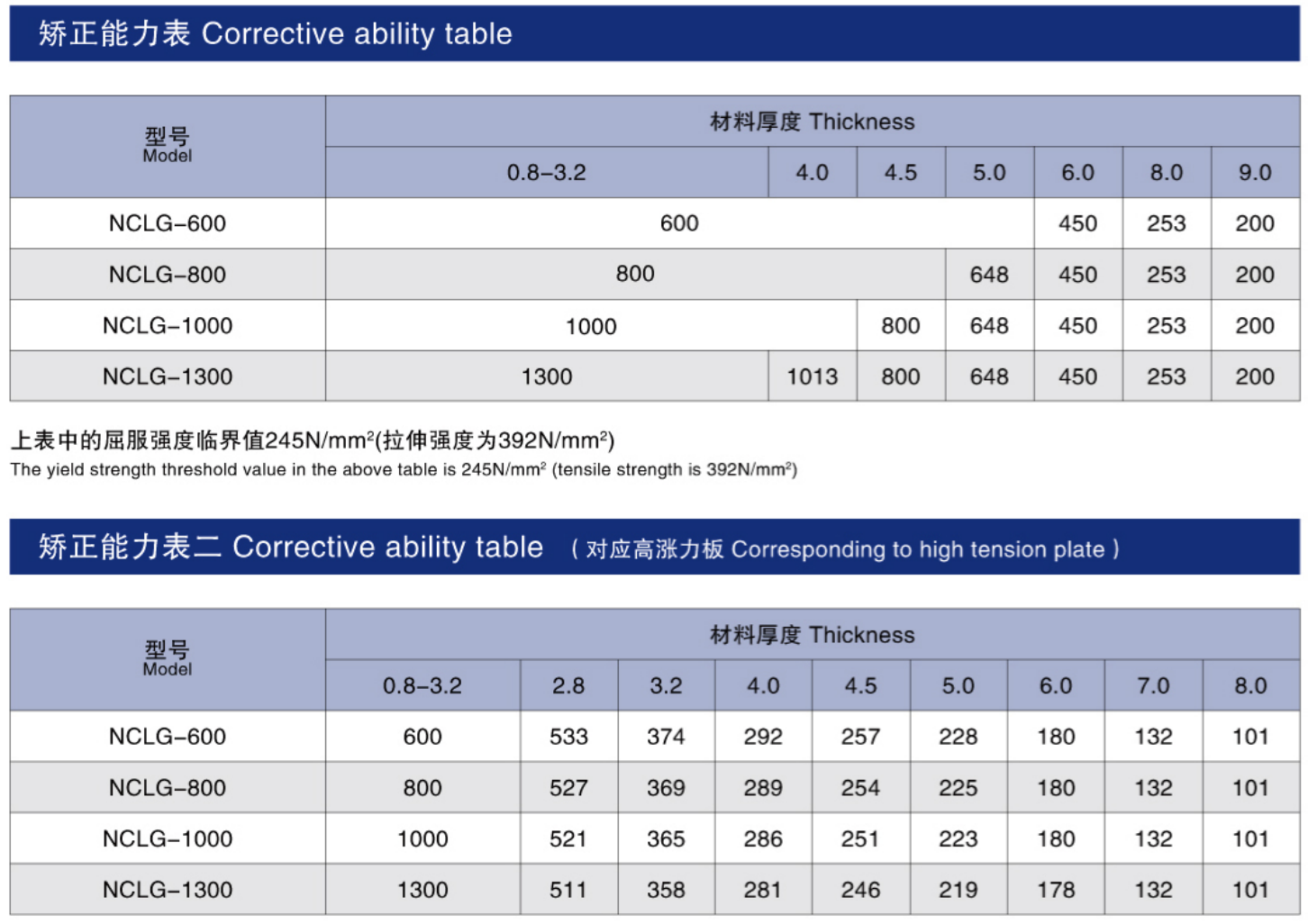

3.Corrective ability table

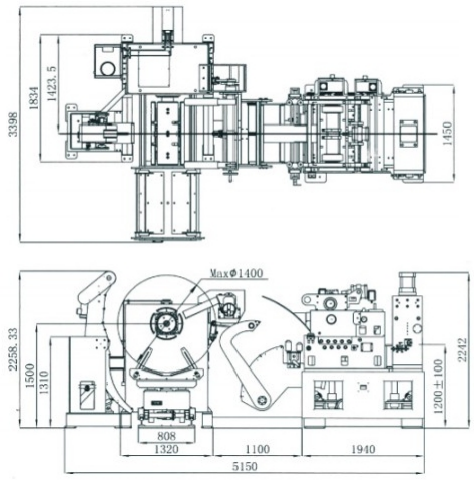

4.Dimensions

5.Equipment usage environment:

① Usage environment:-10 C°+45C°

② Relative humidity:≤95%

③ Work environment power supply:380V±10,50HZ. Three-phase five-wire system(Customizable according to customer requirements)

④ Air pressure:0.5MPa

⑤ Power:About 45Kw

⑥ Production flow: from left to right (can be made according to customer requirements)

6.Suitable material parameters

① Material: Cold rolled sheet, acid washed sheet, galvanized sheet, stainless steel sheet, hot-rolled sheet

② Material surface treatment: no treatment

③ Material thickness: 1.0~8.0mm (please refer to the material correction capability table)

④ Material broadband: 100~600mm

⑤ Yield strength: ≤ 613N/mm ²

⑥ Tensile strength: ≤ 980N/mm ²

⑦ Roll inner diameter: 508mm

⑧ Roll outer diameter: 1800mm

⑨ Roll quality: 5000Kg

7.Main configuration parameters

Projects | Name | Brand | Remarks |

1 | Gear motor | Qiang Zhu | |

2 | Servo motor | Yaskawa,Japan | |

3 | Touch screen (with 5mm protective panel added) | Delta,Taiwan | |

4 | PLC programmable controller | Mitsubishi,Japan | |

5 | Circuit breaker | Schneider | |

6 | Contactor | Schneider | |

7 | Control button | Schneider | |

8 | Relay | Schneider | |

9 | Cylinder | Japan SMC/ Taiwan AirTAC | |

10 | Pneumatic components | Japan SMC/ Taiwan AirTAC | |

11 | Hydraulic Main Components (Solenoid Valve, Pressure Maintaining Valve, Throttle Valve, Pressure Regulating Valve, Pressure Relief Valve) | DOFLUID,Taiwan | |

12 | Oil cylinder+oil pipe+hydraulic box | DOFLUID,Taiwan | |

13 | Photoelectric induction | Omron, Japan | Using two sets of electric eye control method |

14 | Leveling bearings | Famous brands such as NSK/NTN/WGB | |

15 | frequency converter | Delta/Huichuan,Taiwan | |

16 | Servo Driver | Yaskawa, Japan |

Contact: Mr. Alexander Wong

Phone: +8618913853250

Tel: +8618913853250

Email: alexander@dayeepress.com

Whatsapp:+8618913853250

Add: No. 66, Taoyuan South Road, Xuzhou Industrial Park (Jiawang District), Jiangsu Province, China 221132

We chat